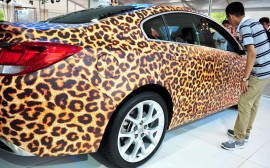

Aqua graphics is also known as 3d immersion transfer printing, cubic printing, hydro graphics, water transfer printing, water transfer imaging. It is a unique decorating process and this technology allows existing product to be decorated without the high cost of re-tooling. The aspect of this 3d technology provides for the image to transfer to desired…

Details

Ultrasonic welding is an industrial technique whereby high frequency ultrasonic acoustic vibration are locally applied to work pieces being held together under pressure to create a solid state weld. It is commonly used in plastics industries especially for joining dissimilar plastics materials. Ultrasonic welding equipment can be easily customized to fit the exact specification of…

Details

Paint filling offers the broadest number of option in terms of material, colour and application. For metal and rigid plastics it is best to use a fast drying, oil based enamel and mineral spirit for cleaning operation. Engraved portion should be smooth, free from burs and should have sufficient depth to hold the paint. A…

Details

It is a process or a technique of pouring an epoxy on a 2D surface to get a 3D effect. Principle of the process is based on the surface tension and the process is widely used on printed labels, logos, emblems and nameplates. A polyester or vinyl based self adhesive label is printed and cut…

Details

Vaccum metallizing is a process of evaporating metals ( commonly aluminum ) in side a vaccum chamber which then bonds on to the desired substrate ( object on which thin Aluminum. Coating is done ) to achieve a uniform metallized layer. In vaccum metallizing a metallic material is placed in a vaccum chamber with the…

Details

Spray painting is a painting technique where a device is used to spray a coat of paint, ink, varnish, etc. through the pressurized air onto a surface of an object. This process may be manual or fully automatic to achieve a uniform coating of a paint, ink, varnish, etc. on an object. This process when…

Details

Pad printing is a method of decorating plastic articles where silicon pad transmit the desired image on the plastic article. Pad printing is a process that can transfer 2D image on to the 3D object. In Pad printing process an artwork is been developed by designer or customer and in respective to the same a…

Details

Screen printing is a printing technique that uses a woven mesh to support an in blocking stencil. The attached stencil form open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edge image onto a substrate. A roller or squeegee is moved across the screen…

Details

Hot stamping is a dry method of printing where a die and foil are used to apply graphics on a surface of an object. Hot stamping is a process in which an engraved image, hot stamping die or type is heated then forced down with a pressure against a part with a marking foil sandwiched…

Details

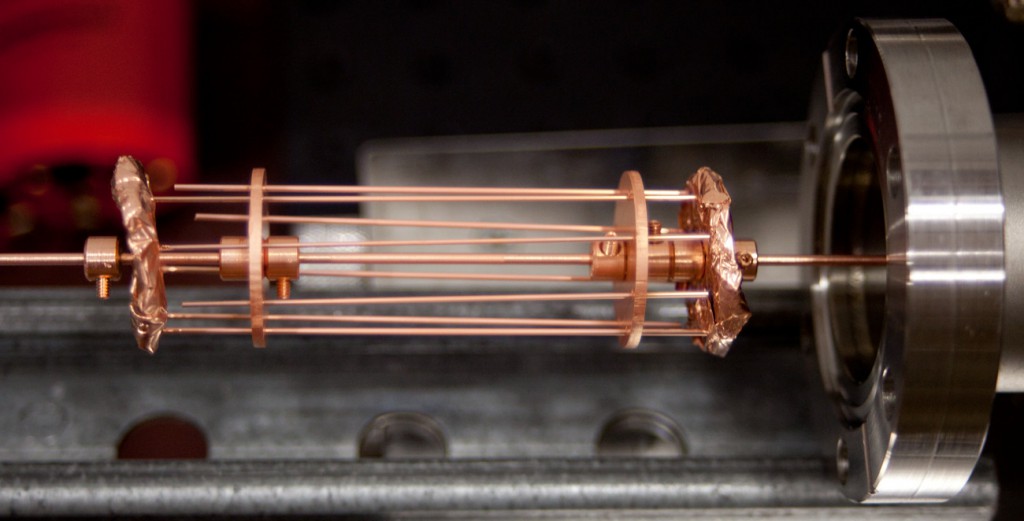

Electroplating is often also called Electro deposition. Electroplating is a process of producing a metallic coating on a surface by the action of electric current. The deposition of a metallic coating on an object is achieved by putting a negative charge on the object to be coated and immersing it into a solution which contains…

Details

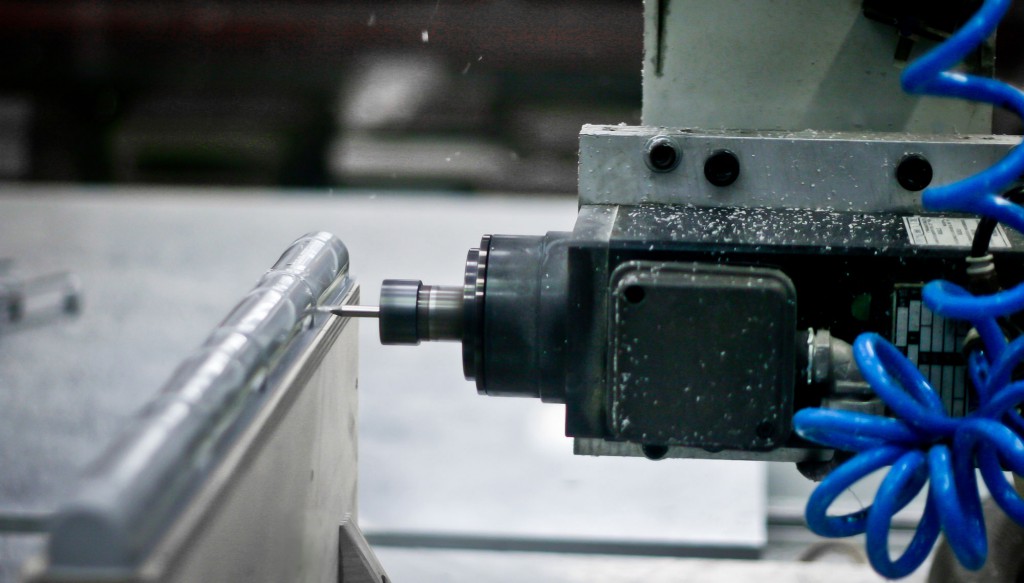

It is a manufacturing process for producing parts from both thermoplastics & thermosetting plastics material. Material is fed into heated barrel, mixed and injected through barrel into a mold cavity where it is cooled and hardened to a configuration of mold cavity and then the article respective to a cavity is ejected from punch side…

Details