Our Products

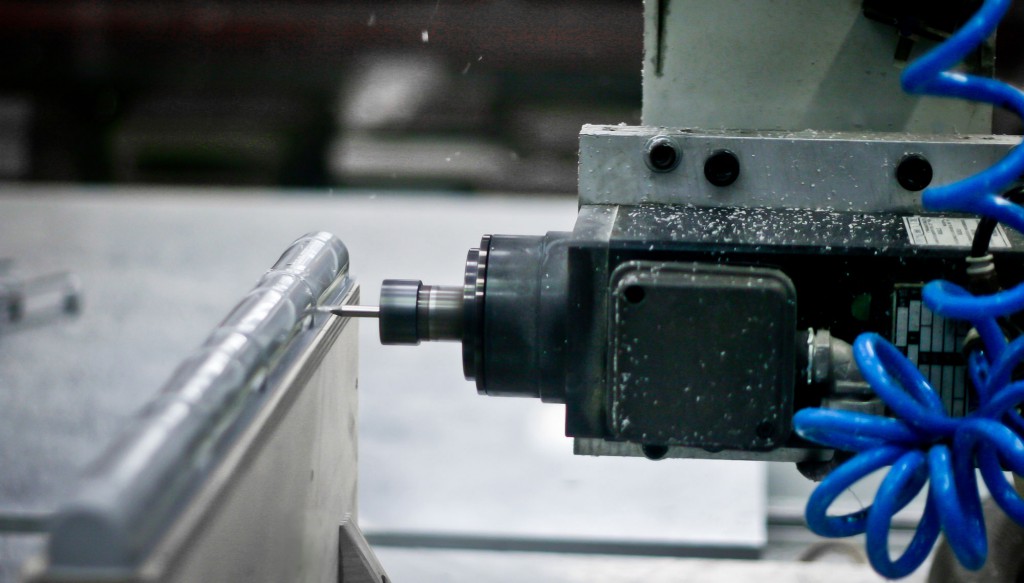

To enhance our productivity, we have a team of excellent mould designer and fully equipped mould designing facility at our premises. This enables us to create moulds, test and utilize them in the production of plastics with an extremely quick turn-around time, this further increasing customer satisfaction.

Our Services

”Injection

”Electroplating“

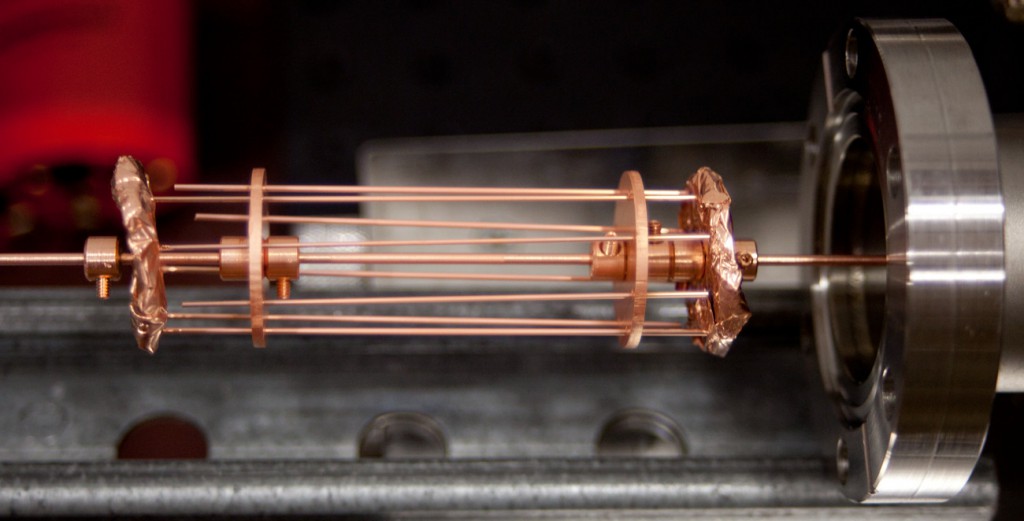

Electroplating is often also called Electro deposition.Electroplating is a process of producing a metallic coating on a surface by the action of electric current.

The deposition of a metallic coating on an object is achieved by putting a negative charge on the object to be coated and immersing it into a solution which contains a salt of the metal to be deposited. And the objected to be plated is put on the cathode of an electrolytic cell. The metallic ions of the salt carry a positive charge and thus attracted to the object and when they reach the negatively charged object, it provides electron to reduce the positively charged ions to metallic form.

”Matallizing“

Vaccum metallizing is a process of evaporating metals ( commonly aluminum ) in side a vaccum chamber which then bonds on to the desired substrate ( object on which thin Aluminum. Coating is done ) to achieve a uniform metallized layer.

In vaccum metallizing a metallic material is placed in a vaccum chamber with the work piece to be coated. The material that is being applied is then heated until it starts to evaporate, this vaporized metal condrnse on the product or work piece as a thin metallic film.

”Screen

Screen printing is a printing technique that uses a woven mesh to support an in blocking stencil. The attached stencil form open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edge image onto a substrate.

A roller or squeegee is moved across the screen stencil, forcing the ink to past the threads of the woven mesh in the pen areas.

”Pad

desired image on the plastic article. Pad printing is a process that can transfer 2D image on to the 3D object.

In Pad printing process an artwork is been developed by designer or customer and in respective to the same a plate is been engraved or etched where the plate contains etched image of the desired artwork.

”SPRAY

This process may be manual or fully automatic to achieve a uniform coating of a paint, ink, varnish, etc. on an object.

This process when paint is applied to an object through the use of an air pressurized spray gun. The air gun has a nozzle, paint basin and air compressor. When the trigger of gun is pressed the paint mixes with the compressed air stream and is released in a fine spray.

”HOT

Hot stamping is a process in which an engraved image, hot stamping die or type is heated then forced down with a pressure against a part with a marking foil sandwiched in between. The area where the die meets the parts is where the ink from the foil is left behind.

”COLOURING“

A paint fill is also known as colour fill. It is a process of painting a recessed area of a surface without getting painted on the area surrounding the recessed portion. These recesses are most often letters and are in different shape and pattern. They are usually created through etching or engraving and in case of plastics it is through injection molding. Because the borders are predefined, paint fills are generally quite easy to do with a simple method by colour pouring or by craft brush.

”DOMING“

Principle of the process is based on the surface tension and the process is widely used on printed labels, logos, emblems and nameplates.

A polyester or vinyl based self adhesive label is printed and cut to shape and size, domed with polyurethane resin then applied to a wide range of products.

”ULTRA

It is commonly used in plastics industries especially for joining dissimilar plastics materials.

Ultrasonic welding equipment can be easily customized to fit the exact specification of parts being welded. The parts are sandwiched between a fixed shaped nest ( anvil) and a sonotrode ( horn ) connected to transducer and a 20khz low amplitude acoustic vibration is emitted.

Our Clients

Contact Us

-

Address:

Excel Estate, Vashier, Valsad, Gujarat, India – 396001 -

Phone numbers:

+91-2632-226661, +91-9825176754 -

Email:

excelshine@hotmail.com