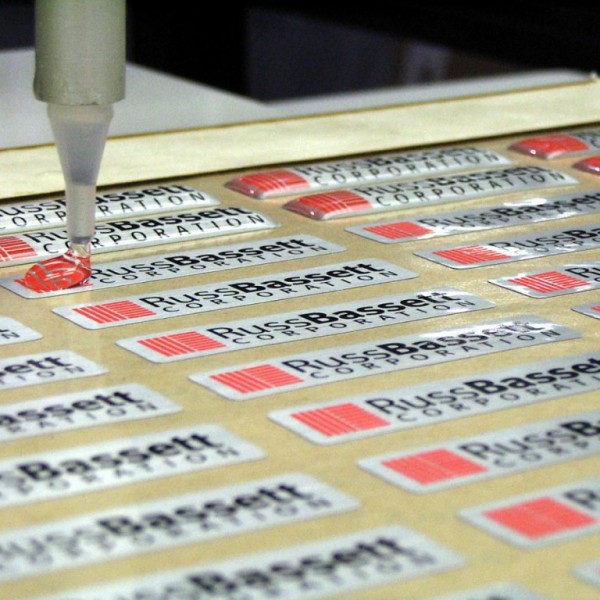

Principle of the process is based on the surface tension and the process is widely used on printed labels, logos, emblems and nameplates.

A polyester or vinyl based self adhesive label is printed and cut to shape and size, domed with polyurethane resin then applied to a wide range of products.

Doming is a process adds value to any shape or size, non porous material by coating the surface with a thick layer of polyurethane resin upto approximately 4mm in height. Polyurethane resin is very durable, tough, long lasting product which cannot be easily scratched or dented. In addition a good quality resin will not get pale yellow when exposed to UV rays and does not present any health and safety issues both in production and final application of cured domed objects.

PU doming are abrasion resistant and are available in hard, medium, soft form. They are chemically prepared and treated to prevent cracks, scratches. PU doming are highly flexible and transparent.

The doming process works on the principle of surface tension to form a bubble of epoxy / resin on the item being decorated without going off the edge of the item. The epoxy / resin is then exposed to low intensity ultra violet light which initiates a chemical reaction causes the epoxy / resin to harden.