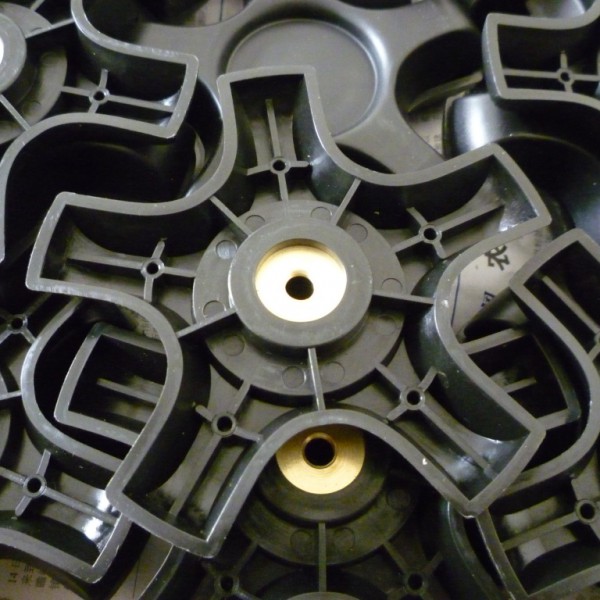

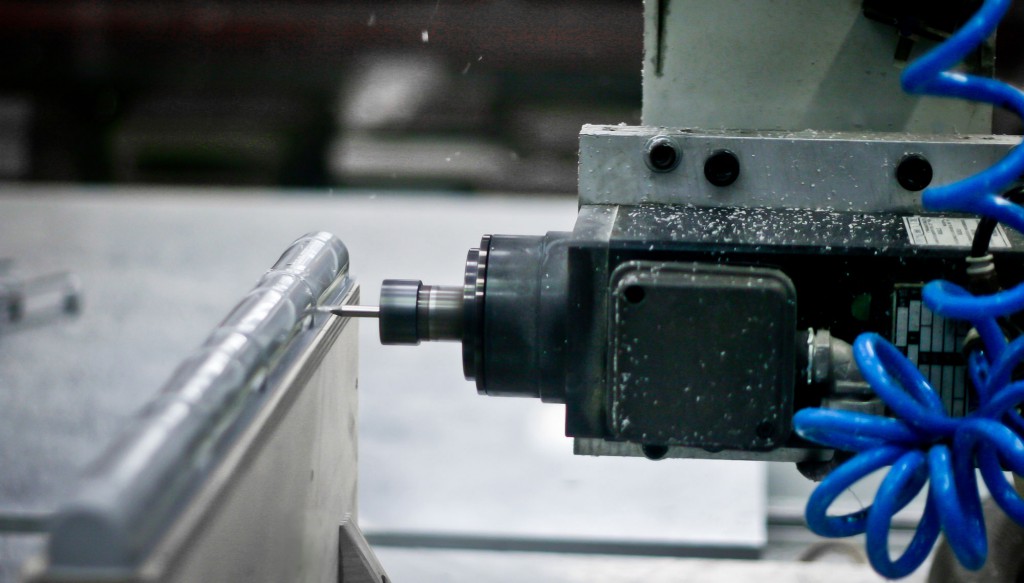

It is a manufacturing process for producing parts from both thermoplastics & thermosetting plastics material. Material is fed into heated barrel, mixed and injected through barrel into a mold cavity where it is cooled and hardened to a configuration of mold cavity and then the article respective to a cavity is ejected from punch side of mold and respectively the production is carried on. An ability to process:

- ABS — Acrylonitrile Butadine Styrene

- PC — Poly Carbonate

- PS — Poly Styrene

- PA — Polyamides 6, 6/6

- PBT — Polybutylene Terephtalate

- PET — Polyethylene Terephthalate

- SAN — Styrene Acrylonitrile

- TPE — Thermoplastics Elastomer

- PP — Polypropylene

- PMMA — Polymethylmethacrylates

- PPS — Poly Phenylene Sulphide

- PEI — Polyetherimide

- PPA — Polyphtalamide

- POM — Polyoxymethylene (Acetel)

- MPF — Melamine Polyster

- PU — Polyurethane

- PF — Phenol Formaldehde

- PEEK — Poly ether ether ketone

- DAP — Diallyl phthalate

- PPO —- Polyphenylene oxide

- PSU —- Polysulfone

Among all these some are filled polymers upto 50% with Glass fibre, minerals like Talc, calcium, calcium carbonate, etc